I make little sculptures and models in my spare time, so I wanted to try to 3D print something that would be difficult to make by hand. My guiding thought was not ‘Gee, what would be cool to make?’ as much as it was ‘What would a 3D printer be uniquely well-suited to do?’. The Design Lab’s Canvas page recommends looking through sites like Thingiverse where people share different design files in order to get started imagining what to print.

A blue 3D printed box made at the Shapiro Library Design Lab being twisted open and closed. Inside is a red object in the shape of a cartoon robot that was also assembled by the author at the Lab using a soldering iron. Attached to this red object is two flashing LED lights.

One of the first designs recommended to me on Thingiverse was this popular preassembled iris box by Emmett Lalish. The “iris” in the name should conjure the part of the eye as opposed to the flower. Like the eye, iris diaphragm mechanisms like the one used to open and close this box are frequently used in photography equipment to control the passage of light. You can see how this mechanism typically works for a flat iris diaphragm with 5 blades below:

A looping animated diagram of the mechanism behind a rudimentary iris diaphragm with five blades. Each blade is kept in place by a single hinge. Moving the outer ring clockwise uniformly rotates the five blades about each of their hinges, opening the aperture. Moving the outer ring counter clockwise closes the aperture by rotating the blades back into place. Source: Wikipedia Commons.

The iris box project was appealing since it has a few aspects that are characteristic of the products of additive manufacturing. If the box were not made by additive manufacturing, one would expect that in order to get the interior pieces in place one would need to open the solid exterior shell, place the interior pieces inside and then patch the incision. But, despite the moving parts, the box requires no assembly or extra pieces like screws — in the parlance of 3D printing enthusiasts, the iris box is a “print-in-place” project. After the print is finished, one just needs to carefully free the blades of the iris from the base and outer shell and the iris diaphragm mechanism should work.

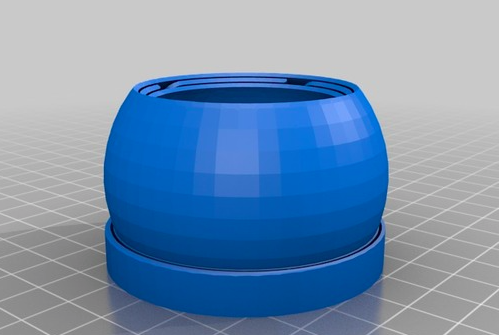

A digital rendering of the iris box while open as viewed from the side. Source: user murdokiwi on Thingiverse.

The success of the box’s simple iris mechanism is predicated on a 3D printer’s ability to manufacture uniform pieces that interlock but do not ultimately fuse during the printing process. Unfortunately, multiple user comments on Emmett Lalish’s version of the iris box suggested that the Shapiro Design Lab’s PRUSA printer was likely to run into difficulties involving fusing while printing. As a result, we chose to print a version by user murdokiwi and, lo, it was a success on our first try.

I am irrationally proud of the results. Why irrationally? Well, it was the Thingiverse community that did the designing and troubleshooting, the PRUSA 3D printer that did the actual manufacturing and the instructors at the Shapiro Design Lab that diligently walked me through the entire process. I can hardly claim I had a hand in the box’s creation, but I, nonetheless, get to walk home from the library with a cool new object.